Creek Pipe local contractor: What clients want to know

Wiki Article

Understanding the Secret Features of Pipeline Solutions and Their Influence On Effectiveness

Pipeline services play a vital role in various industries, influencing operational effectiveness considerably. Secret features, such as sophisticated surveillance modern technologies and maintenance methods, are essential for lessening downtime. Furthermore, regulative compliance warranties safety and environmental management. Nonetheless, the interplay in between layout, framework, and economic elements can complicate these procedures. Comprehending exactly how these elements influence total performance increases crucial questions concerning finest practices and future growths in the area.The Function of Innovation in Pipeline Tracking

As improvements in technology continue to evolve, the value of efficient pipeline surveillance has become significantly obvious. Modern pipe systems count on advanced surveillance tools that boost functional efficiency and safety and security. Technologies such as real-time data analytics, sensors, and drones offer drivers with immediate insights into pipe problems, enabling them to identify leakages, rust, and various other prospective issues prior to they intensify right into considerable troubles.The integration of Net of Points (IoT) devices has changed conventional surveillance approaches, permitting for continual surveillance and automated reporting. This positive method not only lessens dangers however additionally maximizes upkeep timetables and resource allocation. In addition, progressed software application platforms facilitate data visualization and interpretation, equipping decision-makers to respond swiftly to anomalies. Collectively, these technical developments not only improve pipeline honesty however likewise foster environmental stewardship by reducing the possible influence of leaks and spills.

Upkeep Approaches for Enhanced Performance

Reliable upkeep methods are crucial for maximizing pipeline performance. Carrying out anticipating upkeep techniques, adhering to regular assessment procedures, and developing durable emergency situation feedback plans can greatly improve functional dependability. These methods not just minimize downtime yet additionally contribute to the total security and integrity of pipeline systems.Anticipating Upkeep Methods

Predictive maintenance strategies are significantly identified for their capacity to enhance functional effectiveness in pipeline solutions. By leveraging data analytics and keeping track of innovations, these methods enable drivers to anticipate devices failures prior to they occur. This aggressive strategy minimizes unintended downtime, minimizes maintenance prices, and extends the life expectancy of essential properties. Sensors and IoT gadgets play a crucial duty in collecting real-time information, enabling the assessment of devices wellness and performance fads. Machine knowing formulas assess this data to determine patterns and forecast prospective concerns. Consequently, pipeline drivers can schedule maintenance activities throughout non-peak times, optimizing resource allowance and ensuring constant procedure. Eventually, the adoption of predictive maintenance fosters a much more reputable and effective pipe infrastructure.

Regular Inspection Protocols

Routine inspection methods function as a foundation of upkeep approaches aimed at improving effectiveness in pipe operations - Midland pipeline construction company. These procedures include organized assessments of pipeline integrity, concentrating on discovering possible problems before they escalate. Routine assessments typically include aesthetic analyses, leakage detection modern technologies, and stress surveillance to assure peak efficiency. By sticking to recognized routines, operators can determine deterioration, product wear, or obstruction, thus decreasing downtime and repair prices. In addition, data gathered during inspections can educate anticipating upkeep efforts, enabling a proactive technique to pipeline administration. Eventually, routine inspections not just prolong the life-span of pipe infrastructure but additionally add to more secure and extra dependable transport of sources, reinforcing total operational efficiencyEmergency Situation Response Preparation

Emergency action planning is vital for keeping effectiveness in pipe operations, guaranteeing that drivers are prepared to attend to unanticipated incidents quickly and properly. A well-structured emergency situation action strategy consists of clear procedures, marked functions, and interaction methods to mitigate dangers associated with pipeline failings. Regular drills and training boost group preparedness and familiarize workers with emergency situation procedures. Furthermore, having readily available resources, such as spill control tools and emergency contact listings, can substantially decrease action times. By incorporating real-time surveillance modern technologies, operators can rapidly determine and react to problems, decreasing ecological influence and functional downtime. Ultimately, a thorough emergency reaction strategy not just safeguards properties and employees but likewise strengthens the total effectiveness of pipeline services.Regulative Conformity and Safety Specifications

Regulative compliance and safety criteria play an essential role in the pipeline solutions industry. Midland oilfield pipeline services. Following sector guidelines ensures that firms carry out reliable security protocols and run the risk of administration methods. This commitment not just safeguards workers and the environment yet additionally enhances total functional efficiencyCompliance With Industry Rules

Compliance with sector laws is necessary for making certain the security and efficiency of pipeline operations. Regulative frameworks, such as those developed by the Epa (EPA) and the Go Here Pipeline and Hazardous Materials Safety And Security Management (PHMSA), established strict standards that drivers need to stick to. These regulations cover numerous aspects, consisting of pipeline layout, construction, maintenance, and monitoring, assuring that systems operate securely and successfully. Non-compliance can result in extreme penalties, functional delays, and ecological hazards. By sticking to these guidelines, pipeline business not just safeguard public safety and the atmosphere yet also boost their operational effectiveness. Inevitably, regulatory conformity fosters count on among stakeholders, making certain that pipeline solutions can run effortlessly in an affordable landscape while fulfilling legal commitments.

Safety And Security Protocol Application

Effective security method implementation is a necessary component of pipeline procedures, very closely linked to regulatory compliance and security criteria. Sticking to these methods not just assures the defense of personnel however likewise safeguards the setting and infrastructure. look what i found A robust security structure consists of regular training, thorough evaluations, and making use of appropriate safety devices. Organizations should continue to be watchful in updating their methods to show changes in policies and technological improvements. Conformity with well-known safety standards minimizes the threat of accidents and enhances functional performance. Furthermore, a society of safety and security fosters worker interaction and accountability, contributing to total organizational success. Eventually, efficient safety protocol execution is critical in maintaining the honesty of pipe solutions and attaining lasting sustainability in operations.Risk Administration Techniques

Implementing durable risk administration techniques is vital for ensuring that pipeline procedures comply with regulatory needs and security standards. Organizations has to determine possible threats and evaluate threats associated with pipeline tasks. This involves performing comprehensive assessments, utilizing sophisticated monitoring innovations, and preserving compliance with sector guidelines. Regular training for employees on safety procedures boosts situational recognition and prepares teams to react efficiently to emergency situations. Additionally, establishing contingency strategies and performing drills can significantly minimize risks. Collaborating with governing bodies ensures positioning with advancing safety requirements. By focusing on threat management, pipe services can enhance operational effectiveness while safeguarding both the atmosphere and public safety and security. Inevitably, a proactive technique to take the chance of management fosters a culture of safety and security within recommended you read the market.Pipeline Style and Framework Considerations

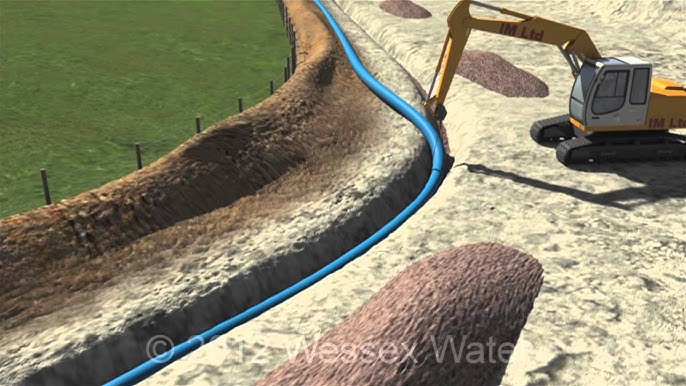

Just how can the style and framework of pipelines influence overall functional performance? The configuration of pipelines plays an essential function in determining their efficiency. Reliable style reduces friction losses, thus decreasing power consumption during liquid transportation. Elements such as diameter, material selection, and layout directly influence circulation prices and upkeep requirements.In addition, critical positioning of shutoffs and monitoring systems boosts operational control and safety. Pipeline services Midland Texas. Facilities considerations, including availability for repair and maintenance, greatly affect downtime and overall productivity

Incorporating sophisticated technology for real-time tracking helps with prompt discovery of leakages or ineffectiveness, making sure swift feedbacks to problems. The total structural honesty, influenced by material durability and ecological aspects, also shapes long-lasting operational success. Subsequently, thoughtful style and durable infrastructure are important for optimizing pipeline efficiency, eventually adding to the integrity and profitability of pipeline services.

Ecological Impact and Sustainability Practices

While the need for pipe solutions proceeds to expand, recognizing the environmental impact and adopting sustainability practices has actually ended up being progressively essential. The building and operation of pipelines can notably affect communities, wildlife habitats, and water sources. To mitigate these impacts, firms are applying innovative modern technologies and techniques aimed at minimizing discharges, stopping spills, and minimizing land interruption.

Sustainability initiatives commonly include using environmentally pleasant materials, boosting power performance, and utilizing renewable power resources to power operations. Furthermore, firms are progressively performing thorough environmental analyses before project initiation, making certain conformity with regulations and stakeholder interaction.

Price Management and Economic Variables in Pipeline Services

As the pipeline industry grows, effective price management and understanding financial elements end up being essential for maintaining competitiveness. Firms encounter different economic stress, including changing material expenses, labor expenses, and regulative conformity costs. To browse these challenges, pipeline service suppliers have to adopt calculated financial planning and budgeting techniques.Investing in innovation can boost functional performance, ultimately decreasing prices gradually. Additionally, reliable project management guarantees that resources are designated efficiently, minimizing hold-ups and unanticipated costs.

Market problems, such as demand for power and geopolitical aspects, also affect financial stability. Companies should continue to be active, changing their techniques in feedback to these exterior factors.

Regularly Asked Inquiries

What Are the Various Types of Pipeline Services Available?

Different sorts of pipe solutions consist of transportation, storage, upkeep, inspection, and repair work. Each service plays an important duty in making certain the smooth movement of materials, boosting security, and lessening operational interruptions across various markets.Exactly How Commonly Should Pipeline Inspections Be Carried Out?

Pipeline examinations ought to be performed on a regular basis, generally every one to 3 years, depending on the kind and condition of the pipeline. Extra regular inspections may be essential for older or risky pipes to ensure safety and security and integrity.

What Are the Key Causes of Pipeline Failings?

The primary sources of pipeline failings include deterioration, defective construction, material issues, external damage, leaks, and functional errors. Each element contributes considerably to possible dangers, highlighting the relevance of regular maintenance and tracking for safety and security.Just How Can Companies Boost Pipeline Service Dependability?

Companies can enhance pipe solution reliability by executing routine maintenance schedules, making use of advanced tracking innovations, carrying out complete inspections, buying worker training, and adopting proactive threat management strategies to expect and reduce possible failures.What Duty Do Operators Play in Pipeline Services?

Operators play a vital function in pipe services by making certain secure transportation, maintaining equipment, checking system integrity, working with maintenance, and reacting to emergencies. Their experience directly influences functional efficiency and decreases disruptions in service distribution.Report this wiki page